Fast Facts:

- Volume – 200-2000 CFM

- Pressure – 30-250″ H20 (1-9 psig)

- Drive System – Belt-Driven

- Motor – 3-Phase, 480/230v, 50/60Hz, 3 to 40 HP available

Applications:

Industrial drying and cleaning with blow-off nozzles or air- knives, tank aeration, vacuum/exhaust.

Why Choose an Air Power® Centrifugal Blower?

- Highest Efficiency – No other industrial blower can match the performance of an Air Power® blower at a lower energy cost.

- Highest Performance – Outperforms any industrial blower of equal motor size and similar flow range.

- Best Durability – Outlasts any equally sized blower. Belt Life: 8,000 hours (1 year at 24/7 operation) Bearing Life: up to 80,000 hours (10 years at 24/7 operation)

Vortron’s Air Power® Blower Lineup

Each Air Power blower model (X40, J70, Z40e and Z80) is available in different speeds and motor sizes. We can help you select the right model, speed, and motor size for your application. Please contact us for assistance.

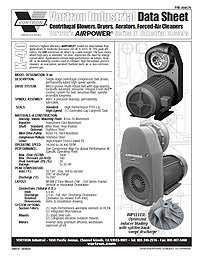

X40 Series

Volume: 200-700 CFM

Pressure: 40-100″ H20

Outlet Size: 3.5″ OD

Inlet Size: 5″ OD

J70 Series

Volume: 200-700 CFM

Pressure: 100-130″ H20

Outlet Size: 3″ OD

Inlet Size: 4″ OD

Z40e Series

Volume: 700-1600 CFM

Pressure: 40-160″ H20

Outlet Size: 3.5″ OD

Inlet Size: 5″ OD

Z80 Series

Volume: 400-2000 CFM

Pressure: 50-250″ H20

Outlet Size: 4″ OD

Inlet Size: 5″ OD

Inside Air Power

Vortron’s Air Power line of compact centrifugal blowers has raised the bar for industrial blower performance. Volume and pressure not attainable with competitive single stage industrial blowers are now easily reached. All Air Power centrifugal blower models are aerodynamically optimized to meet particular flow and pressure requirements. All models are clean-sheet designs that were developed from the ground up to deliver the best efficiency, best durability, and best performance of any industrial blower available today. With peak isentropic efficiencies up to 80 percent, no other compact industrial blower comes even close.

A closer look reveals that Vortron Air Power® means business. All models are based upon modern, high-efficiency centrifugal compressor design principles, and feature aerodynamic performance that is vastly superior to the common, outdated blower technology that is currently still being used in most industrial blowers today. Vortron holds manufacturing and quality to aerospace turbomachinery standards, which enables Air Power® centrifugal blowers to consistently meet operating points and efficiency levels well beyond the reach of the competition. With an Air Power® blower, the elusive 100″H2O at 1000 CFM is not only easily reached, it’s achieved at 80 percent efficiency!

High-Efficiency Compressor Stage

Air Power® centrifugal blower compressor stages are highly evolved and thoroughly tested designs, originating from years of experience in the production of thousands of centrifugal superchargers. A simple visual examination clearly shows the difference. All Air Power® compressor stages incorporate sophisticated impeller designs, coupled to either a channel or vaneless diffuser, with a progressive scroll, or volute exit stage.

Air Power® Impellers

Air Power® Impellers incorporate advanced features such as aerodynamically optimized inducer blading and splitters, and in some cases, backsweep and exit rake – all based on the pressure/flow objectives for the particular blower. Rather than simply changing the speed of the blower for different “models,” each Air Power® blower is aerodynamically unique, so that the best possible performance is delivered for your application.

In order for a centrifugal blower to take advantage of impeller work effectively, flow must be diffused efficiently so high levels of pressure can be produced at minimum loss. Exclusive to Air Power® centrifugal blowers, Vortron incorporates diffusers, each matched optimally to the flow physics of the impeller, with numerous iterations tested until maximum level of efficiency is attained. A matched volute further collects and diffuses to result in additional pressure rise.

What is the result of this process? Isentropic efficiency up 80%! In fact, all Air Power® centrifugal blowers reach at least 75% efficiency, with over than 70% for the majority of the flow range (surge to choke). These efficiency levels are achieved at pressures which eclipse the performance of most competitive, single-stage industrial blowers by far. For Example, the Air Power® Z40e centrifugal blower can deliver 170″ H2O (WC) pressure at 1200 CFM, at an efficiency of 78%! Looking at from another standpoint, a 20HP Z40e blower easily reaches the elusive operating point of 100″ H2O at 1000 CFM.

Fresh-Aire® Cooled Spindle Assembly

Take note – Air Power® spindle assemblies are different from what you typically see in a industrial blower. Instead of the blower spindle housing being exposed to the internal hot compressed air stream, as is common with competitive industrial blowers, Air Power® centrifugal blowers incorporate a Patented Fresh-Aire® cooling system, which supplies an uncompressed, cool air stream to the spindle housing and bearings. This limits harmful temperature rise in the critical seal and bearing elements. Vortron has found that limiting temperature rise in its bearings increases longevity significantly. In general, a 20-degree increase in operating temperature will reduce grease life by one-half. In addition, an Air Power® centrifugal blower’s higher efficiency further limits temperature rise and extends the life of the bearings even more.

The blower’s bearing system incorporates angular contact (A/C) ABEC-9 class precision bearings. To better support the belt load, a duplex pair or bearings is positioned outboard. A/C bearings generate less friction and are better suited for use in high-speed blowers, hence less heat and temperature rise than deep groove ball bearing systems seen in competitive centrifugal blowers. The result is a greater margin for speed and load capacity, which equates to enhanced durability and extended blower life.

Air Power® Tensioning and Belt Life

In today’s industrial blowers, automatic tensioning systems are seen as standard, but Air Power® centrifugal blowers incorporate a precision-machined idler system with proprietary features such as dual bearings for extended life. In addition, the entire blower drive system is enclosed and cooled by the Patented Fresh-Aire system. The reasoning behind this is simple: generally speaking, an 18-degree belt temperature rise can cut the life of the belt in half! Temperature rise in the Air Power® idler system and belt is managed by carrying away heat, and again, reliability and operating life are maximized. Industrial customers always place a high demand on idler and belt performance – Vortron Industrial has engineered a solution!

Air Power® Precision Drive System Components

Engineered and manufactured entirely at Vortron Industrial, Air Power® precision drive system components raise the level of quality and sophistication in the Air Power® centrifugal blower line. Vortron machines blower pulleys from billet stainless steel and balances them to ISO G4 tolerances. Another unique part of the Patented Fresh-Aire system, the drive pulley with integral cooling fins is manufactured from cast aluminum, hard anodized, and precision balanced. This design makes sense – the large aluminum pulley allows for additional capacity to conduct heat and carry it away from the drive belt.

Air Power® Cover and Cast Mounting Plate

Vortron’s customers continue to demand centrifugal blowers not only with greater reliability and enhanced performance, but quieter operation as well – a tough bill because making pressure quietly is not easy. But, Vortron’s ingenuity has done it again. As another part of the exclusive Fresh-Aire® system, the molded drive cover and cast aluminum mounting plate incorporate a sound-attenuating design which further manages potential sources of noise within the blower.

Vortron’s Warranty and Service Program

Vortron Industrial maintains its commitment to quality with continued investment in state-of-the-art manufacturing and assembly equipment to enable the production of centrifugal blowers that meet the performance demands of today’s industry. No other company, building centrifugal blowers today, holds tighter manufacturing tolerances than Vortron Industrial.

CAPA Industrial will provide you with a quote and help answer any questions that you may have about our centrifugal blowers, including:

- Will this blower work for my application?

- Which blower model should I use?

- What accessories do I need?

- How much energy will I save?

- How soon can I get one?

Documents

About Vortron Industrial

Vortron Applications

Vortron Development

Vortron Case Study – Battery Manufacturer

Vortron Energy Savings

Compressed Air vs Vortron

| Part No. | Item Name | Price Inc. GST |

| Vortron Head Units | ||

| VOR-HU-X40 | X-40 Head Unit Only | $7,159.00 |

| VOR-HU-J70 | J-70 Head Unit Only | $POA |

| VOR-HU-Z40E | Z-40e Head Unit Only | $8,259.00 |

| VOR-HU-Z80 | Z-80 Head Unit Only | $9,359.00 |

| . | ||

| Vortron Installation Kits | ||

| VOR-IK4 | X-40, J-70 & Z-40e Installation Kit | $5,389.00 |

| VOR-IK8 | Z-80 Installation Kit | $5,499.00 |

| Installation Kit Includes: Mounting Plate, Cover, Head Unit Pulley, Motor Pulley, Belt, Tensioner, Dampener Strut and Mounting Bolts. | ||

| . | ||

| Vortron Gear Drive | ||

| VOR-IKG | X-40 & Z-40e Gear Drive | POA |

| . | ||

| Vortron Head Unit Pulleys | ||

| VOR-14-1500 | Vortron 14-Rib Head Unit Pulley, 1.500″ | $379.00 |

| VOR-14-1635 | Vortron 14-Rib Head Unit Pulley, 1.635″ | $379.00 |

| VOR-14-1740 | Vortron 14-Rib Head Unit Pulley, 1.740″ | $379.00 |

| VOR-14-1850 | Vortron 14-Rib Head Unit Pulley, 1.850″ | $379.00 |

| VOR-14-1910 | Vortron 14-Rib Head Unit Pulley, 1.910″ | $379.00 |

| VOR-14-RET | Vortron 14-Rib Retaining Bolt and Washer | $109.00 |

| . | ||

| Vortron Head Unit Accessories | ||

| VOR-HU-TAB | Volute Retainer Tab, Each (Qty 6 Req.) | $18.10 |

| VOR-HU-BTAB | Volute Retainer Tab Bolt, Each (Qty 12 Req.) | $2.40 |

| VOR-HU-BOLT | Head Unit to Mounting Plate Bolt, Each (Qty 8 Req.) | $2.90 |

| . | ||

| Vortron Mounting Plate and Blower Drive Parts | ||

| VOR-MNT-PLA4 | Mounting Plate, X-40, J-70 & Z-40e | $1,199.00 |

| VOR-MNT-PLA8 | Mounting Plate, Z-80 | $1,269.00 |

| VOR-MTR-PLAB | Motor to Mounting Plate Bolt, Each (Qty 5 Req.) | $4.90 |

| VOR-MTR-BAL | Motor Pulley, 12″ | $1,209.00 |

| VOR-MTR-COU | Motor Pulley Taper Lock Coupler | $179.00 |

| VOR-MTR-COUB | Motor Pulley Taper Lock Coupler Bolt (Qty 10 Req.) | $2.40 |

| VOR-MTR-TENS | Tensioner Assembly, Inc. Bolt & Washer | $929.00 |

| VOR-MTR-DAMP | Tensioner Dampener Strut, Inc. Bolts | $349.00 |

| VOR-BELT-14PK | 14-Rib Supercharger Drive Belt | $169.00 |

| VOR-MNT-COVC | Chassis Cover (Includes Mounts and Nuts) | $919.00 |