VT-140 Model supports flowrates up to 140lb/min.

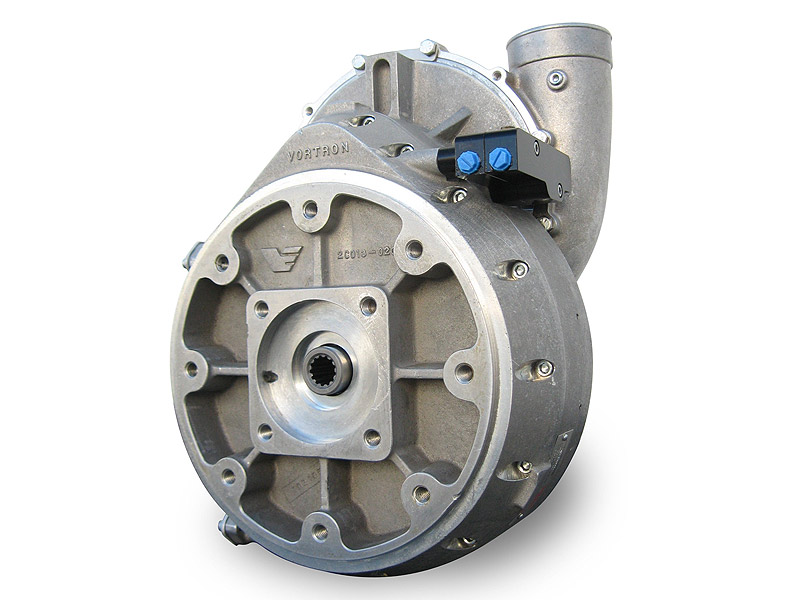

Vortron’s VT compressor provides unique air moving solutions for complex needs. Developed for aircraft de-ice / anti-ice GSE applications, the patented VT compressor now serves many industries. New adaptations are now available to support broad application in aircraft GSE, industrial air moving, ultra high-velocity blow-off, sparging, bulk transfer conveying, and many others. Can be electrically or hydraulically driven; with direct-coupled hydraulic drive resulting in 125HP rating at under 100lbs package size. Performance range from 5 – 15 psi and up to 1600 CFM; 14 psi at 100 lbs/min typical. Adiabatic efficiency ratings up to 80%.

Applications

- Blow-off

- Sparging

- Debris Removal

- Shallow Vacuum

- Air Cooling

- Bulk Conveying

Industries Served

- Aircraft GSE

- Military

- Food Processing

- Rubber and Plastics

- Agriculture

- Municipal WWT

Performance:

The VT gearcase can be equipped with various compressor stages to achieve the performance objectives of a particular application. Recommended compressor stages include the X (“X-Trim” or “X40”) (79% peak efficiency) for typical deicing applications and the Z (Z40e) (80% peak efficiency) for applications requiring higher flowrates. Detailed performance curves and compressor efficiency data can be found on available compressor maps.

Operating Speed:

20,000-45,000 RPM (Impeller)

Flowrate:

500-1600 SCFM (see maps)

Pressure Ratio:

Up to 2.5 PR, nom. (see maps)

Internal Gear Ratio:

8.75:1

Connections:

» Inlet – 5.00 in.

» Discharge – 3.50 in

Gearcase Shaft Input:

SAE J498b, Class 1 Flat Root Side Fit Spline. SAE B, 16/32 P 30° Involute

Compressor Materials:

» Housing: Volute: A356-T6 Aluminum

» Impeller: Investment Cast Aluminum

» Shaft and Gearing: Heat-treated Alloy Steel

Operating Temp (Ambient):

-20°C to 50°C

Environmental Requirement Compliance:

Can meet or exceed: Moisture, Vibration, MIL, Industrial requirements.

Recommended Drive System:

Can be electrically or hydraulically driven. Parker F12-30 motor is suggested for hydraulic applications.

CAPA Industrial will provide you with a quote and specifications on a VT Gear Drive blower for your application, and answer questions such as:

- Will this work for my application?

- How much power will it consume?

- What RPM will provide the performance that I need?

- What hardware do I need to connect to the gearbox?

Vortron Centrifugal Blower Documents

X-40 Series Data Sheet (PDF)

Z-40e Series Data Sheet (PDF)

About Vortron Industrial

Vortron Applications

Vortron Development

Vortron Case Study – Battery Manufacturer

Vortron Energy Savings

Compressed Air vs Vortron

4 Page Flyer – Air Power Blowers (PDF)

Return on Investment (PDF)

Selection Guide (PDF)

Typical Industrial Blower System Operating Map (PDF)

CleanTech Magazine Article Blower Efficiency (PDF)